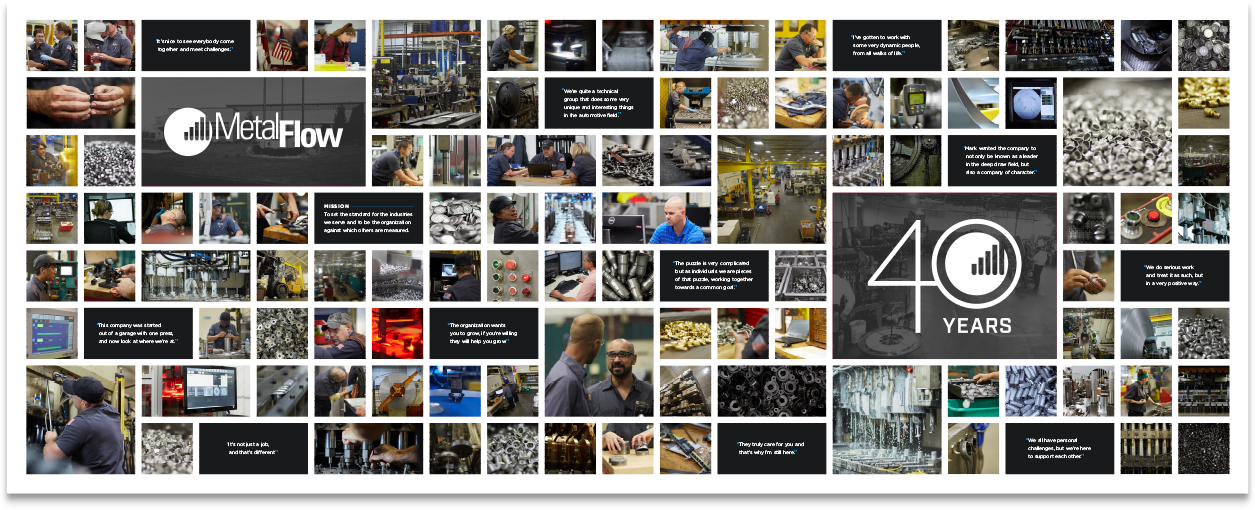

Metal Flow is a rapidly growing, innovative metal forming company with extensive value-added manufacturing technologies focused on bringing value to customers and to the community we serve.

The people of Metal Flow Corporation are deeply committed to providing the highest quality processes and products to customers around the world. We produce high volume, technically sophisticated custom metal components through the deep draw process using a variety of metals, and are actively seeking candidates who have an interest in working in a precision environment to create safety critical, quality product that serves primarily the global automotive industry. Successful team members will thrive in a fast-paced production environment while still maintaining organization, attention to detail, and a quality focus.

Metal Flow Offers:

- Career Advancement and Competitive Wages

- Medical / Rx / Vision / Dental / Life / Disability / Flex Spending Plan (Health & Dependent Care)

- Company Paid Short Term Disability and Basic Life

- Company Paid Health Savings Account Contribution

- Company Funded Child Care Discount Program

- Pine Rest Employee Assistance Program

- 401(k) Plan

- Paid Time Off

- Immedidate eligibility for 10 Paid Holidays

- Air-Conditioned Plant

- Free Uniforms and washing services!

- Family Summer Picnic, Holiday Party, and other Celebratory Events

- Recognition Committee and team member engagement programs

- Safety Committee and Environmental Committee participation opportunities

- Balance Program - Reimbursement of up to $100 for any 1 wellness experience on an annual basis

- 24/7 Onsite Fitness Center

- Quarterly Performance Sharing Program

- Education & Apprenticeship Opportunities

- Tuition Assistance Program

- Tool and Die Maker 4 Year Apprenticeship Programs

- Maintenance Apprenticeship Program

Metal Flow is an Equal Opportunity Employer. Metal Flow Corporation is committed to providing equal employment opportunities (EEO) to all employees and applicants for employment without regard to race, color, religion, sex (including sexual orientation and gender identity), national origin, age, disability, marital status, veteran status, genetic information, or any other protected characteristic under applicable law. In addition to federal law requirements, Metal Flow Corporation complies with applicable state and local laws governing nondiscrimination in employment in every location in which the company has facilities. This policy applies to all terms and conditions of employment, including recruiting, hiring, placement, promotion, termination, layoff, recall, transfer, leaves of absence, compensation and training. Metal Flow Corporation expressly prohibits any form of workplace harassment based on race, color, religion, sex (including sexual orientation and gender identity), national origin, age, disability, marital status, veteran status, genetic information, or any other protected characteristic under applicable law. The company also prohibits retaliation against any employee who makes a complaint or participates in an investigation regarding possible EEO violations. If you require a reasonable accommodation to assist with any part of the application and/or hiring process, please contact us at hr@metalflow.com.

Metal Flow participates in the E-Verify program, a service of the U.S. Department of Homeland Security and the Social Security Administration. As part of our commitment to a lawful workplace, we use E-Verify to confirm the employment eligibility of all new hires. Applicants must provide documentation that establishes their identity and eligibility to work in the United States. The E-Verify system will be used to verify this information. For more information about E-Verify, please visit the E-Verify website.

Resources:

Journeyman Tool and Die Maker

Journeyman Tool and Die Maker