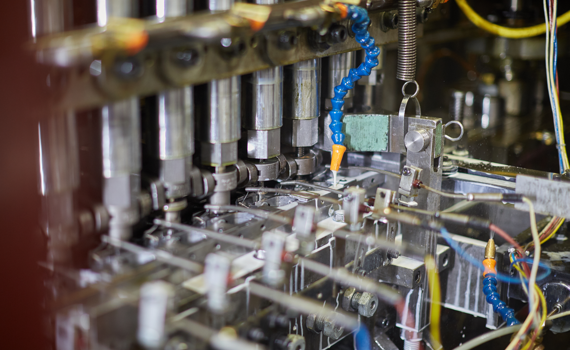

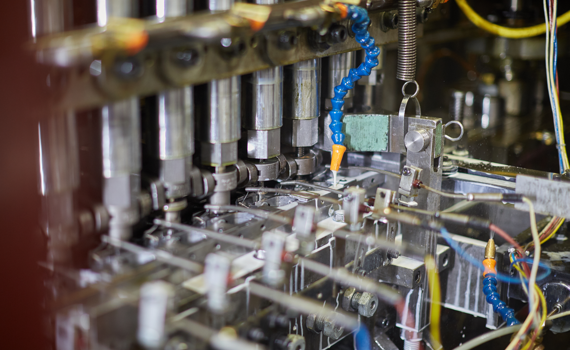

ICOP Presses

ICOP stands for Individual Cam Operated Plungers. These presses come in various sizes, with versatility in the number of stations and tonnage. Since each station has its own cam and plunger, an ICOP press is really like… Learn More

Use this page to explore the types of technology we offer to build components and see what types of products our different machines are capable of making.

ICOP stands for Individual Cam Operated Plungers. These presses come in various sizes, with versatility in the number of stations and tonnage. Since each station has its own cam and plunger, an ICOP press is really like… Learn More

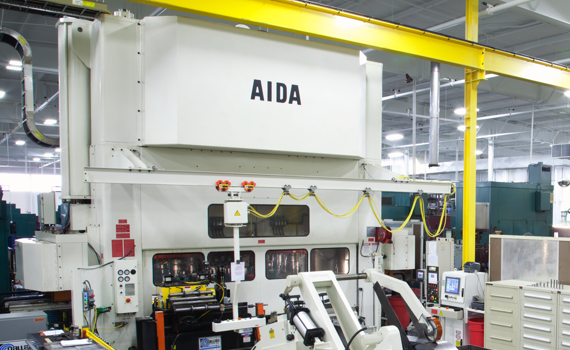

Our Large Presses allow us capability to build larger and thicker components due to higher tonnage and larger bed size. Common applications include airbag components, spark plug tubes, and fuel filters. Learn More

Progressive Die uses similar press technology to our large, die-set presses, but much different tooling technology. Instead of using “fingers” to grab the part and transfer to the next station, Progressive Die technology… Learn More

MetalFlow has a number of specialized machines to meet our customers’ component needs, including welding, bending, and single-hit machines. Learn More